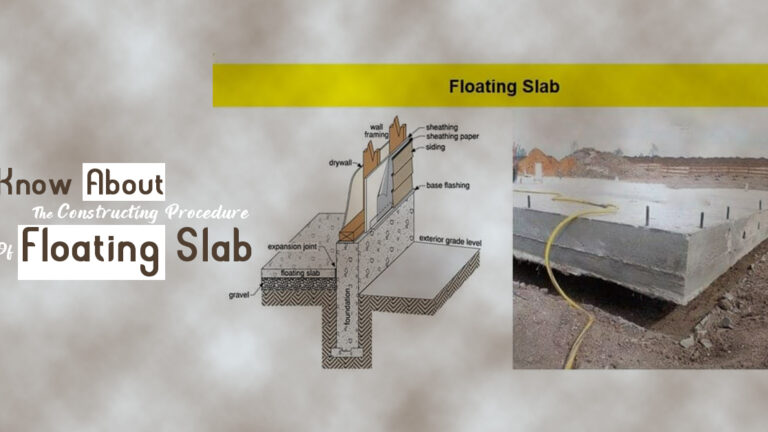

The floating slab means laying a concrete slab over the ground without external support. The construction of the floating slab includes two phases where the footing of the floating slab is constructed first, and the floor’s center is filled with concrete. The construction of floating slabs significantly minimizes the preparation of ground. This slab variant is employed in cases where the structure necessitates a minimal bearing capacity. It is a fitting foundation for petite structures, eliminating the need for a deeper foundation and supplementary infrastructure. Hence, Sathvik, one of the best civil engineering companies in Chennai, explores the construction procedure for these foundations.

How To Construct A Floating Slab?

The floating slab construction establishes a secure foundation that supports the building weight. As mentioned, floating slabs are more frequent in home additions, sheds, and garages, where substantial foundations are unnecessary. In contrast to traditional slab construction, these floating slabs have demonstrated superior suitability and cost-effectiveness.

Preparation Of Site

The initial phase involves a thorough examination of the location of the floating slab construction. Clearing the trees, debris, and small shrubs is the foremost task. Subsequently, Sathvik, one of the best builders in Velachery, develops a comprehensive excavation plan detailing specific areas for digging and soil disposal.

Excavation Process

Following the necessary preparations, the next phase involves excavating the site. Excavating the slab area, ensuring alignment with the specified level. During this stage, create drainage channels along the sides to facilitate the proper drainage of water called gravel base. The excess water will be drained by covering the channel with gravel and geotextile. Also, ensure to encase the channel with a waterproofing substance.

Laying The Base For Gravel

In this phase, the gravel is applied across the area, removing the excess water.

Slab Reinforcement Process

The next phase involves arranging the reinforcement according to the design. It is crucial to ensure that the overlap in reinforcement does not concentrate in one specific location but is distributed in a varied manner. Moreover, the reinforcement needs to align with the specifications of the slab to enhance the structural strength.

Shuttering

Next, the shuttering process commences. The formwork demands an even surface, precise alignment, and meticulous craftsmanship. It is crucial to affix cover blocks after completing the shuttering to prevent the opening of the formwork during the pouring of concrete.

Concrete Placement

The concrete is produced on-site using a machine or ready-made concrete substance for the floating slab. These materials are thoroughly mixed in an appropriate mixer to attain optimal strength. Proper compaction is essential during this process, and it can be achieved through manual efforts or by machine, based on the area and workmanship. After 24 hours, the formwork should be taken down.

Curing

Curing is a crucial step in ensuring the desired strength of the concrete slab. Following the removal of the formwork, the slab should undergo a seven-day curing process. It involves spraying water to facilitate the curing and enhance the concrete’s overall strength.

Hence, these are the crucial steps in constructing the floating slab securing the foundation of the small structures. Therefore, approach Sathvik, one of the best individual home construction builders in Chennai, for a successful floating slab construction.